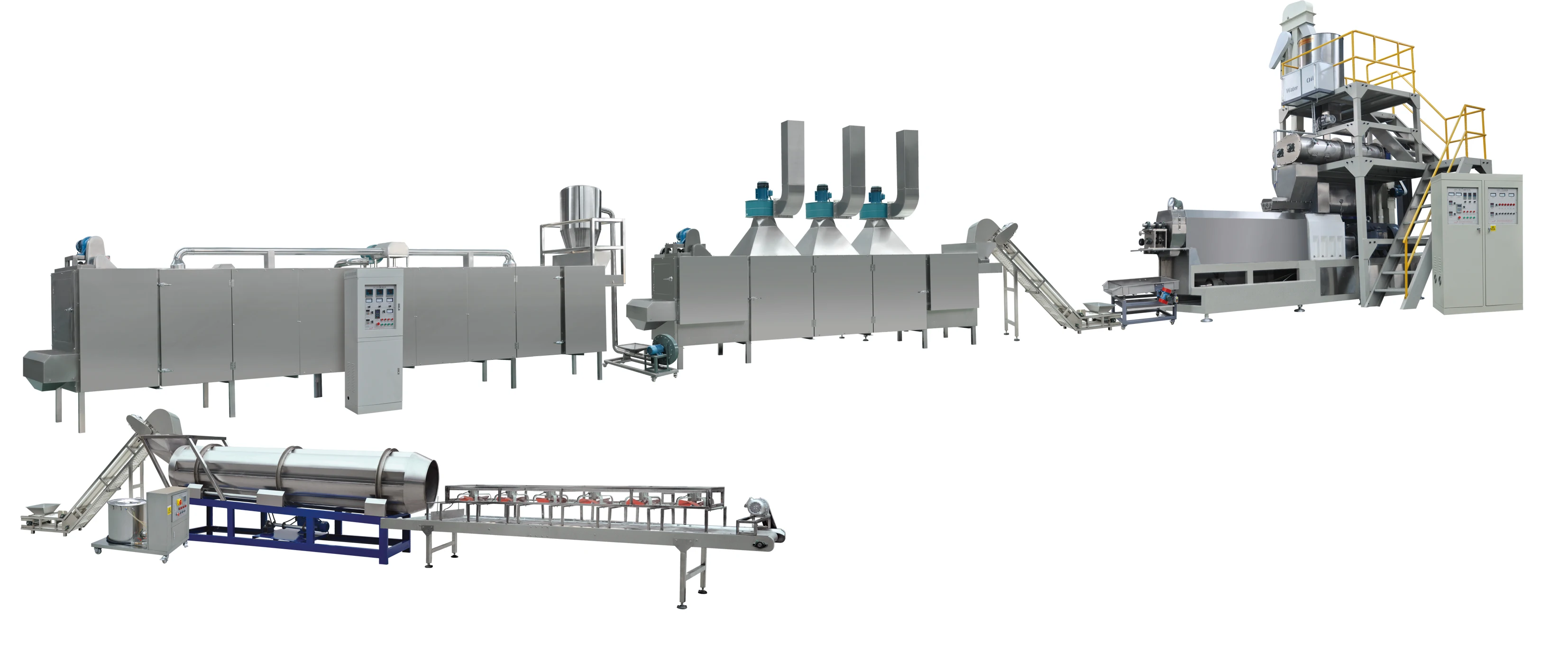

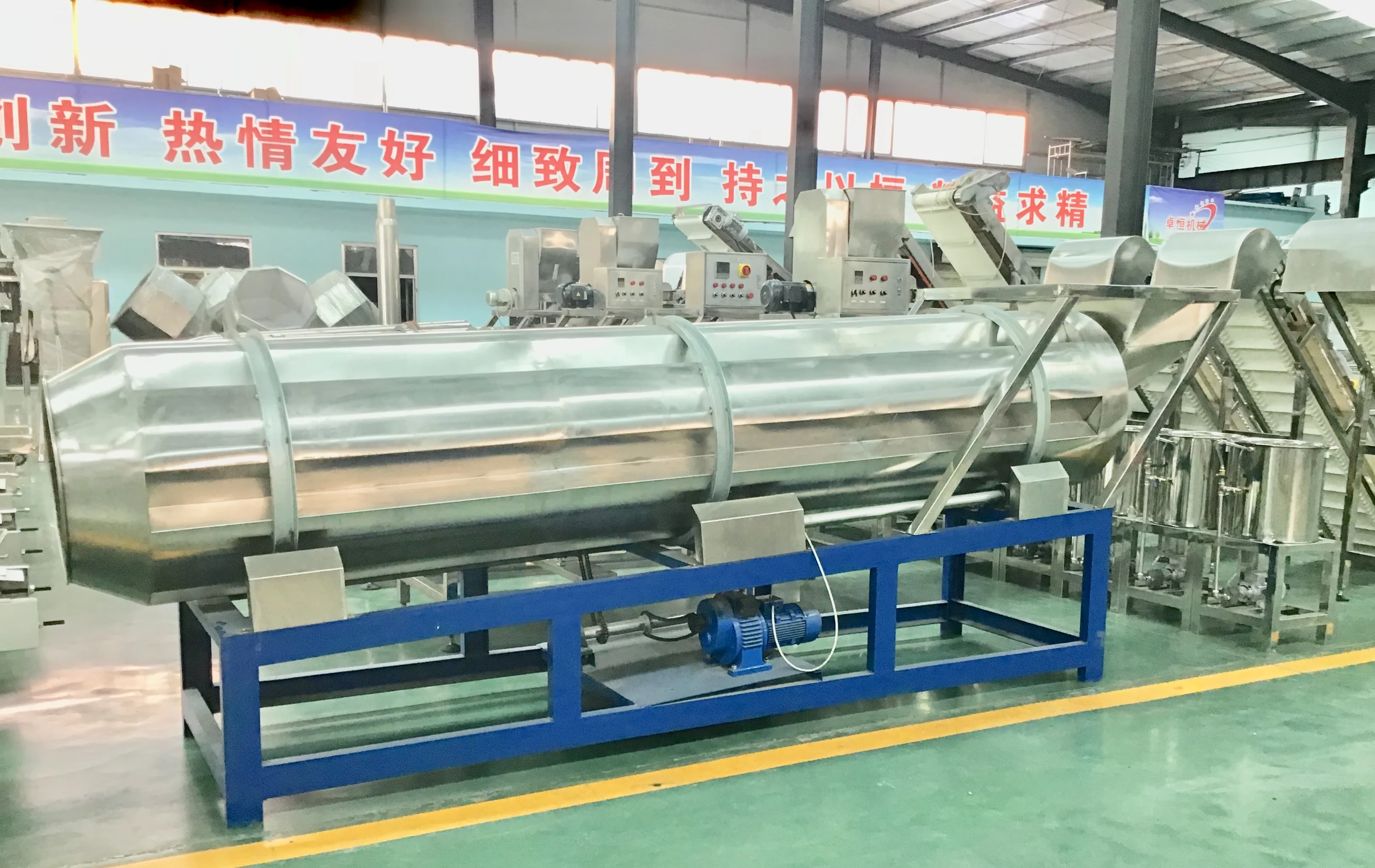

Large Capacity Twin Screw Extruder Floating Fish Feed Pellet Machine

Fish feed machine line also suitablr for making animal food ,like dog cat pet. The extruder adopt the doube screw which can suitable many differerent type materials with self-cleaning.

2). The fish food whole line fully continuous and automatic.

3). Zhuoheng provide basic fish food formula according to your require.

4). The final fish food shapes and sizes can be various by changing the mould.

5). Supply different size mould free of charge.

6). Packing machine could be supplied to work with the fish feed production line (depending on your require)

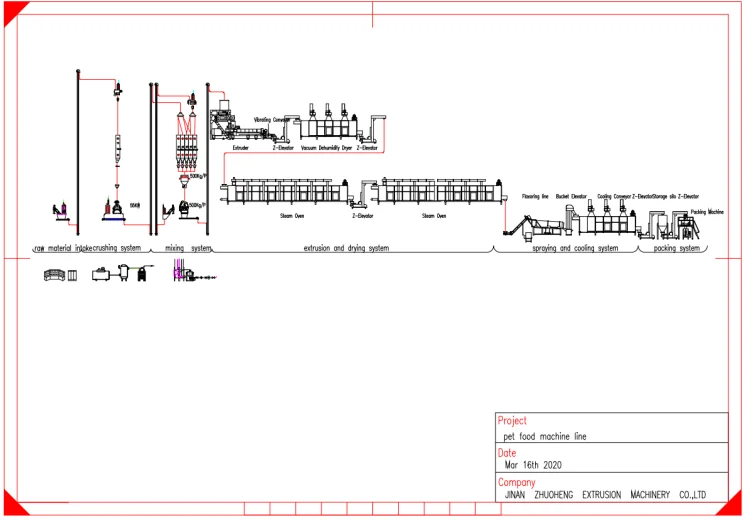

Flow Chart

Our engineer could design the layout drawing according to your dimension of the factory for the fish feed machines.

Model | Installed Power(kw) | Power Consumption (kw) | Capacity(kg/h) | Dimension(m) |

ZH65 | 110kw | 70kw | 120-150 | 25*3*3 |

ZH70 | 138kw | 95kw | 200-250 | 28*3*3 |

ZH85 | 240kw | 160kw | 500 | 30*3*3 |

ZH95 | 330kw | 230kw | 1000-1200 | 50*3*3 |

ZH115 | 400kw | 280kw | 2000 | 60*6*15 |

ZH135 | 500kw | 350kw | 3000 | 60*6*20 |

Raw Material

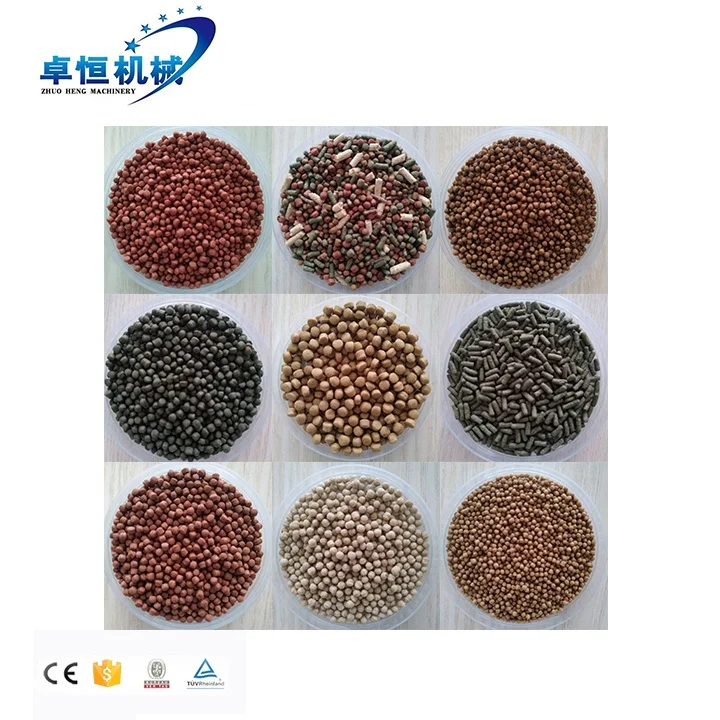

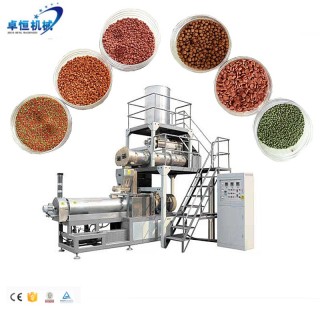

Fish feed samples made by our machines

diameter from 0.2mm to 20mm

Equipment list in the fish feed production line:

output, improving the stability of the extruder operation, prolonging life of t the whole extruder unit.

Adjustable Transit Speed Of Net Belt With Accurate Temperature Control Device. Sliding Board Bottom Of Dryer For Easy Cleaning. Hot Wind Cycle Device Makes Heating Energy Equally In The Dryer

Double-Roller Chain And Chain Drive Make Stable And Smooth Running.

The oil sprayer sprinkle the atomized oil to the products in the drum.By continuous rolling material, the drum will make oil and seasoner evenly adhere to the surface of products. To prevent feed leakage, the hoister is used wavy baffle belt.The oil sprayer can bear high temperature and pressure. Safe and durable. Mixing atomized oil and

Inverter to adjust the speed of spices. Easy to control.

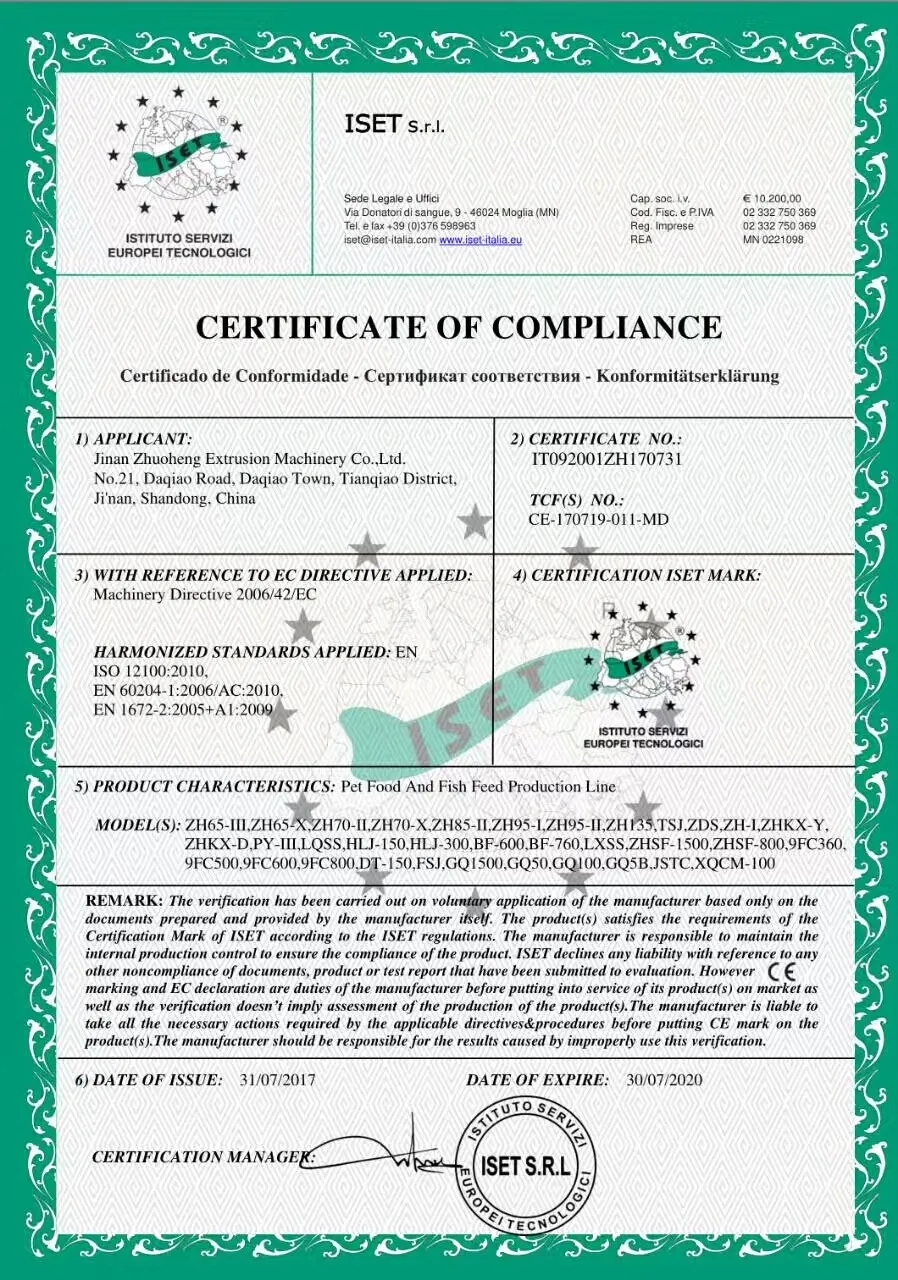

Jinan Zhuoheng Extrusion Machinery Co.,LTD established in 2008, has always been the professional manufacturer and the leader for advanced and high efficient extrusion food machinery in this field all over the world.

* Provide the professional advice about the market, equipment, process, material, packing, etc.

* Assist you to choose equipment, design process flow, and perfect workshop layout. If needed, we can supply service in your factory.

* Make compensate plan to the material change according to your product, and perform the production at site.

* Specially design and manufacture machine, practice test, and provide relevant training as customer required.

* Provide reasonable packing and transportation plan, send technician to install, debug machine and train your workers.

* Two years guaranty time, preferentially supply spare parts.

* Design and process similar type of spare parts of import equipment.

Packing

Outer Packing---Wooden case

Inner Packing----Wrapped with plastic film.

Delivery :

20 GP, 40 GP,40HP container by Land or Sea.

20-40 working days

Q1. Are you a manufacturer or a trading company?

Answer: a professional manufacturer of food & feed extrusion machine.

We have own factory and R&D department. SGS has certified our company on site.

Q2. What is your payment terms?

Answerhigly recommend to use Alibaba's Trade Assurance.

T/T :30% prepayment,70% before delivery. L/C at sight is available. Other payment is negotiable.

Q3. Do you offer guarantee for the products?

A: Yes, we offer 2 years warranty to our products.

Q4. What about the lead time?

A: Regular products:20-30 working days

Customizable products:30-40 working days.

Q5. Can you provide food or feed formula ?

A: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer's formula.

Q6. What after-services do you provide?

A: Send engineers for installation, trial running and training workers at customer's site.

Handling the problems occurred during use. Supply spare and wearing parts on discount.

Help customers to solve any other problems .

Q7. Is configuration(allocation) fixed standard?

Answer: No, it is flexible, we will equip machines based on your requirement.

Q8. Can I come to check your company(Jinan Zhuoheng extrusion machinry co,.ltd)

Answer: Welcome to visit us! We will show our machines in our factory.

Q9. Do you have shipping agent for delivery?

Answer: Yes, we have reliable shipping agent. They can offer a good freight and take care the process very well.

Q10. Can you test our formulation with your extruder?

Answer: As long as you trust on us, we can test your basic formula, then you can see the outcome and place order without any hesitation.

Q11. Why the price in the web is a range?

Answer: As we have many models, and the production lines' configuration are various. So we will equip machines based on customers' specific requirement. So, the price range is for reference.