Fish Feed Pellet Production Line

1. Our Fish Feed Pellet Production Line main motor of the extruder brand is SIEMENS.

2. Relay: ABB or customized.

3. Converter( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta,Pioneer,CHNT or Schneider.

4. All the electric device brand can be customized as you need.

5. Dyer&Oven is also the very important machine in the whole production line, it's source can be Electricity, Gas, Oil or stream.

6. Machine material generally is stainless steel, as customer require 304 / 211 all can be made.

7. Our Guarantee Time is 2 year.

8. After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

9. Certificate: CE, SGS, BV

Fish Feed Pellet Production Line

Simple Description

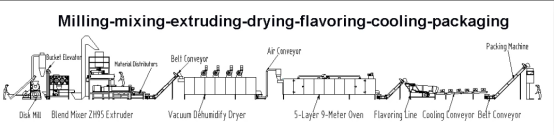

* Fish Feed Pellet Production Line used to produce various size fish feed pellet. We have different capacity production line for customer choose. Like smallest capacity line is 120-150kg/h; bigger is 200-250kg/h; 500kg/h and 1000-1200kg/h

2 Ton/hr and 5 ton/hr production line also provide.

Change the formula, machine can make floating and sinking fish feed pellet two types according customer need.

* We get different size feed pellet for different ages fish, By changing different mold.

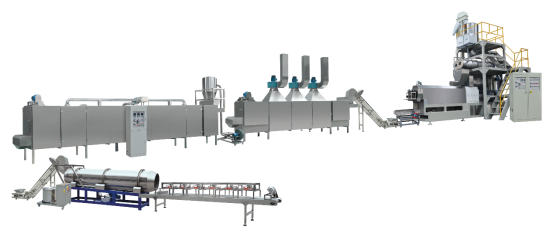

* Our Fish Feed Pellet Production Machine adopt Double Screw Extrusion Technology, different from single screw extruder, it's highly automatic, easily operate and maintain, stable performance are the reasons why popular in the pet food machine market nowasays.

* And the most important advantage of our Fish feed Production Line is That Production Line also can be used to make other shapes pet food pellet, like for cat, dog, shrimp, bird etc.

a. Raw material

The main raw materials of our fish feed production line are, rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

b. Different capacity extruder

C. Different size of fish feed pellet

d. Advantages of Fish Feed Pellet Processing Machine

1. We specialize in high capacity fish feed pet food making extruders.

2. The screw material: Alloy steel (38CrMoAL) by nitriding process. High strength and wear-resting.

a).With good self-cleaning ability, it’s unnecessary to remove the barrel and screws for cleaning.

3. It adopts speed-adjusted converter on feeding system, extrusion system and cutting system.

4. Adopted the Delta inverters, ensure the extruder better running.

5. The gearbox has automatic lubrication function, which prolong service life of gears.

6. Cutting knife is fixed in the die head seat, rotary cutting driven by V-belt.

Company Information

Jinan ZhuoHeng Machinery Co., Ltd is an industry and trade integrated enterprise, established since 2008 year , which has 20 years experience engineers. The company is committed to R & D extrusion machinery and related ancillary equipments.

Packing

Inner packing------- Wrapped film

Outer packing------ Wooden cases

Certificates

FAQ

1. Are you a manufacturer or a trading company?

We are professional manufacturer of food & feed extrusion machine.

2. What's the price of your machines?

Different type machine in different price, welcome to contact us and get the details.

3. What is your payment terms?

T/T or L/C; by T/T 30% as down payment, 70% by T/T before delivery, L/C before shipment.

4. Can you provide the formula ?

We provide basic formula for each cooperate customer.

And help customer to study new formula according customer’s local raw material.

5. What is the workshop size required?

Engineer can help draw the concrete machine layout according customer's factory size.

6. Warranty time?

We provide 2 years.