Automatic pasta macaroni making machine

1.This machine line can use wheat flour or durum/semolina/as main material to make different shapes pasta,like tube,elbow,screw,shell,etc.

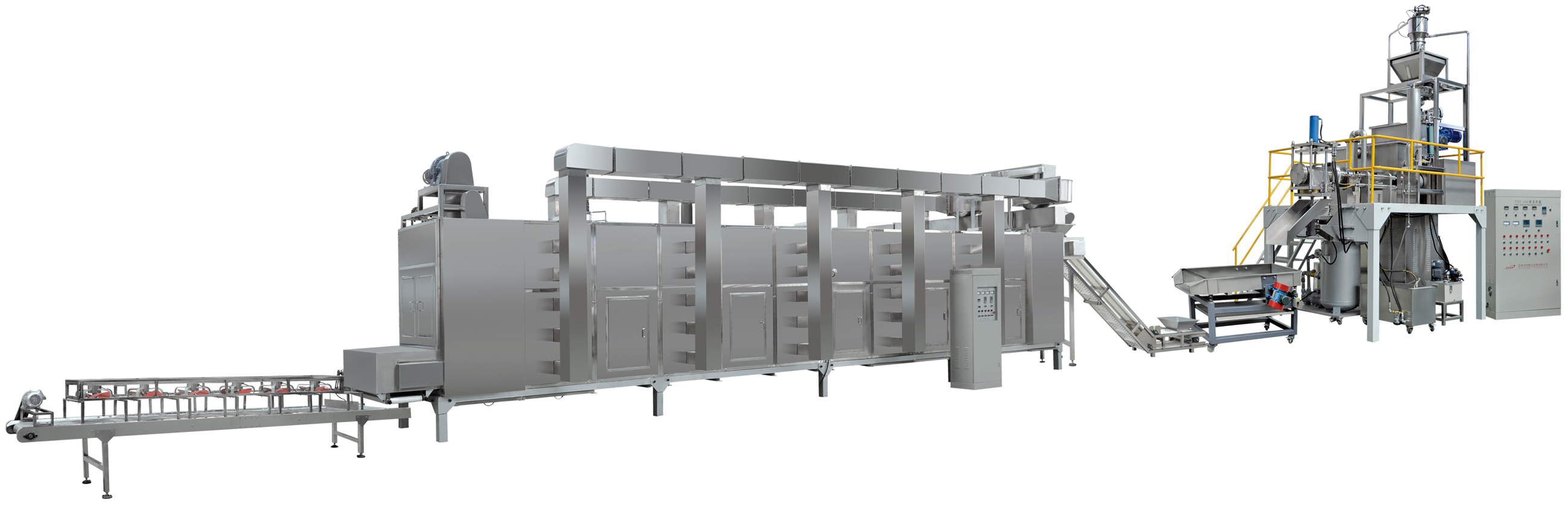

2.Process flow of production:Material mixing-Extrusion shaping-Pre-drying-Drying-Cooling&Convey-Packing.

3.Equipment configuration is perfect,advanced production technology,good quality products,simple and reliable operation,is the ideal equipment to make pasta /macaroni.

1.Product Description

1.The pasta macaroni making machinery adotps most advanced technology in the word Making water

and flour more fully mixed together to produce a variety productions in different shapes which are

popular in the market, such as crispy pea, shell, screw, square tube, round tube, wave etc.

2.Our engineer studied in Italy before with rich vacuum extruder technology and experience.

the mold is imported from Italy.

80-100kg/ h extruder unit (Cold extrusion technique.The process temperature 30-50℃) Dimension:1600*2000*1800 Power: 12.5kw |  |

1.Extrusion Forming Unit is consist of Mixer,Scraper lift and Pasta Extruder,cuter system,cooling system. | |

Model:TXF-160 160-200kg/h extruder unit (Vacuum negative Cold extrusion technique. Process Temperature: 35-65 ℃ Dimension: 2.5*3*3.5m Power:45kw |  |

300kg/h ,400kg/h ,500kg/h and more ..... | |

1. Vacuum feeding system: it will conveyor the flour to the storage bin automatic.The feeding speed can be controlled.Under bin,there is a air-lock valve. 2. High Speed Flour Mixer is a device for mixing flour and water thoroughly by high speed stirring. The motor drives the stirring shaft to run at high speed, and at the same time, water is added to the barrel quantitatively through the water pipe. The flour and water are stirred and mixed in the tank and conveyed to the primary mixing tank. 3. Mixing system:There are two tank for mixing ,after primary mixing with water ,flour will mixing again under vacuum environment. 4. Extrusion Forming Unit includes automatic water supply, circulation water cooling system, and die assembly. 6. vacuum system:consists of vacuum water tank, vacuum pump, vacuum buffer tank, vacuum pipe, vacuum pressure gauge, check valve and three-way deflation valve. 7. The automatic watering system includes storage water tank, water pumps, water inlet and outlet pipes, quantitative valve, flow meter and water tower. Function: add water to the raw material (flour) in quantity according to the technological requirements of the product. | |

2.Processing line

Material mixing-Extrusion shaping-Pre-drying-Drying-Cooling&Convey-Packing.

| 80-100kg/h Pasta Macaroni Making Machine line |

|

| 160-220kg/h Pasta Macaroni Making Machine line with Vacuum System |

|

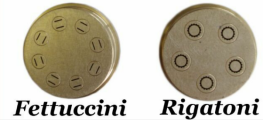

3.Some samples

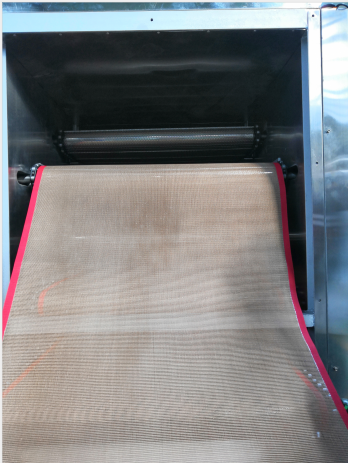

4.About Dryer

Type: Gas/diesel  |

|

1.There are some fan on the top of oven tha can delivery the hot air to both side of the air flue,then spread the heat air to every layer of the oven.And the location of both side air flue is different,which makes the volume of the hot air evenly and heating evenly. |

5.Our Customers

Our company has already exported countries:

Asia { Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq,

Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan }

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine.Poland }

North America { Canada }

South America { Brazil, Bolivia }

Oceania { New Zealand }

Russia kurstans Sweden East Timor

Pre-Sales Service:

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service:

* Training how to instal the machine

* Supply the formula

* Engineers available to service machinery overseas

7.Packing &Loading